Sustainable

The increase of CO2 in the atmosphere has continued to grow since the Industrial Revolution, especially in the past 30 years. The concentration level increased by 25% 200 years after the Industrial Revolution, and in the past 30 years, the concentration level has increased by 50%. At present, the global average surface temperature is about 1ºC higher than before the Industrial Revolution.

Based on the estimated average temperature changes over the next 20 years, global warming is expected to reach or exceed 1.5ºC. The global average sea level rose by 0.20 meters from 1901 to 2018, at a faster rate than any century in the past 3000 years. It will threaten the living environment of some animals, while also leading to desertification, causing an increase in plant diseases and insect pests.

Circular Solutions

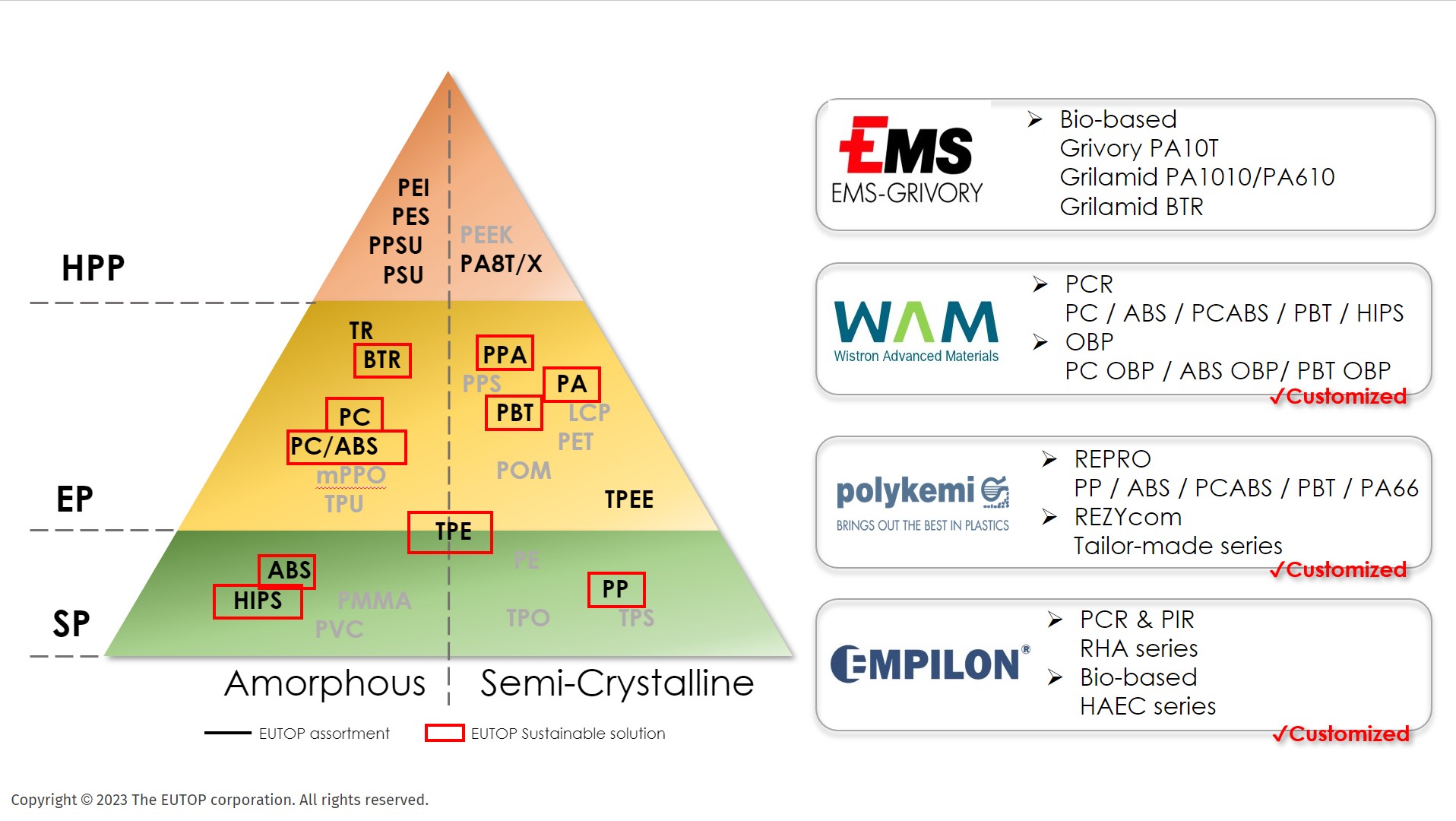

Sustainable Polymers from EUTOP

PCR

WAM

In the ever-evolving landscape of engineering plastics, sustainability has emerged as a critical driving force. WAM (Wistron Advanced Materials), a global leader in close-loop and PCR solutions, has been at the forefront of this movement, pioneering the production and supply of high-quality PCR materials since 2012.

WAM’s extensive experience and expertise have resulted in the development of mature technologies for producing PCR materials with unwavering stability and consistency in quality. This commitment to quality has earned WAM the trust of numerous OEMs worldwide, making them a leading supplier of PCR materials.

Diversified PCR Product Line

WAM boasts a comprehensive range of PCR products, catering to diverse applications and needs. Their product portfolio includes:

- PC (Polycarbonate)

- ABS (Acrylonitrile Butadiene Styrene)

- PC/ABS Blends

- High-Impact Polystyrene (HIPS)

- ABS/OBP (Ocean-Bound Plastics) Blends

- PC/OBP Blends

- PBT/OBP Blends

With PCR content ranging from 5% to 99%, WAM provides designers and material selectors with ample options to optimize their product designs while minimizing environmental impact.

WAM’s dedication to sustainability extends beyond product quality to encompass comprehensive certifications. Their PCR materials are backed by a range of certifications, including GRS (Global Recycled Standard), ITE (Institute of Textile Engineers), UL (Underwriters Laboratories), TÜV (Technischer Überwachungsverein), OBP (Ocean-Bound Plastics), and LCA (Life Cycle Assessment). These certifications demonstrate WAM’s adherence to stringent environmental standards and provide assurance to OEMs regarding the sustainability credentials of their PCR materials.

Partnering for a Sustainable Future. WAM’s unwavering commitment to sustainability has made them a trusted partner for numerous OEMs globally. As the demand for sustainable solutions in engineering plastics intensifies, WAM is poised to play an even more significant role in shaping the future of this industry. By joining forces with WAM, you can embark on a transformative journey towards a more sustainable future, reducing your environmental footprint and contributing to a greener world.

Empilon

The Empilon RHA Series provides two options for recycled TPE: PIR (Post-Industrial Recycled) and PCR (Post-Consumer Recycled). With PIR and PCR percentages ranging from 40% to 60%, this series offers a sustainable choice while maintaining good bonding performance. All recycled resources used for Empilon RHA are traceable with GRS certification. Available from Shore A60 to A80.

Hotai is committed to innovation and quality, continuously investing in research and development to develop new and improved TPEs that meet the evolving needs of its customers. The company’s commitment to quality has earned it the trust of numerous OEMs worldwide, making it a leading supplier of TPEs.

Polykemi

In the ever-evolving landscape of engineering plastics, sustainability has emerged as a critical driving force. Polykemi, a leading supplier of engineering plastics, has been at the forefront of this movement, pioneering the production and supply of high-performance recycled polymers (repro) and renewable resource-based polymers (rezycom) since the early 1990s.

Polykemi’s repro and rezycom product assortment

Polykemi offers a comprehensive range of repro and rezycom products, catering to diverse applications and needs. Their product portfolio includes:

- Repro PP: Polypropylene (PP) is a versatile and widely used engineering polymer. Polykemi’s repro PP is made from post-industrial and post-consumer recycled PP, and it offers the same properties as virgin PP.

- Repro ABS: Acrylonitrile butadiene styrene (ABS) is another popular engineering polymer. Polykemi’s repro ABS is made from post-industrial and post-consumer recycled ABS, and it offers the same properties as virgin ABS.

- Rezycom PP: Rezycom PP is a renewable resource-based PP that is made from plant-derived materials. It offers the same properties as virgin PP, but it has a lower environmental impact.

- Rezycom PBT: Rezycom PBT is a renewable resource-based polybutylene terephthalate (PBT) that is made from plant-based materials. It offers the same properties as virgin PBT, but it has a lower environmental impact.

With PCR content ranging from 5% to 99%, Polykemi provides designers and material selectors with ample options to optimize their product designs while minimizing environmental impact.

Polykemi’s dedication to sustainability extends beyond product quality to encompass comprehensive certifications. Their repro and rezycom materials are backed by a range of certifications, including GRS (Global Recycled Standard), ISCC (International Sustainability & Carbon Certification), and OK biobased. These certifications demonstrate Polykemi’s commitment to using sustainable materials and reducing their environmental impact. Partnering for a sustainable future.

Bio-Based Polymers

Empilon HAEC

Sustainability is at the forefront of Empilon’s innovations, and the Empilon HAEC Series embodies this commitment. With Shore A hardness ranging from 60 to 80, this series offers bio-based TPE with a high percentage of bio content (>60%), excellent touch feeling, and ease of 2K molding.

EMS-Grivory

Embrace a future of sustainability with GreenLine, EMS-GRIVORY’s groundbreaking range of bio-based polyamides. Harnessing the power of nature, GreenLine products are crafted from the renewable resource of castor oil, offering a compelling alternative to traditional crude oil-based polyamides. This innovative approach not only reduces our environmental footprint but also delivers exceptional performance, ensuring that you don’t have to compromise on quality for sustainability. From the flexibility of Grivory HT to the resilience of Grilamid 1S and 2S, each GreenLine product offers a unique set of properties, catering to a wide spectrum of applications. Whether you seek high heat resistance, superior hydrolysis resistance, or crystal-clear transparency, GreenLine has the solution to match your needs. Unlike conventional biodegradable polymers, GreenLine products retain their exceptional durability, ensuring that your products withstand the rigors of everyday use. Their longevity rivals that of traditional crude oil-based polyamides, offering long-term value and sustainability.

Join us in shaping a greener future with GreenLine. By incorporating GreenLine into your design and production processes, you’re not just making a choice for the environment; you’re making a statement about your commitment to sustainability. Embrace the future of responsible manufacturing and experience the transformative power of GreenLine.

Grilamid 1S (PA1010) and Grilamid 2S (PA610)

Embrace a future of sustainable innovation with Grilamid 1S (PA1010) and Grilamid 2S (PA610), two bio-based polyamides that offer exceptional performance and environmental credentials. Made from renewable castor oil, these innovative materials seamlessly blend sustainability with the exceptional properties of traditional PA12 and PA610.

Key Features:

- High to very high bio-content: Up to 99% bio-based content, contributing to a reduced environmental footprint.

- Properties similar to those of PA12 and PA610: Unparalleled performance, comparable to traditional polyamides.

- Low moisture absorption: Excellent dimensional stability and resistance to hydrolysis.

- Tough and durable: Range from flexible to high stiffness, with excellent impact resistance and toughness.

- Excellent UV and chemical resistance: Resistant to environmental factors and harsh chemicals.

- Low density: Lightweight and easy to process.

- Versatile processing capabilities: Ideal for injection molding and extrusion.

- Exceptional adhesion: Grilamid 1S (PA1010) bonds seamlessly with bio-based Grilamid BTR grades, enabling innovative overmolding and sandwich molding processes.

Harness the Power of Nature, Elevate Your Performance. Grilamid 1S (PA1010) and Grilamid 2S (PA610) represent a significant leap forward in bio-based polymer technology. By combining sustainability with exceptional performance, these innovative materials are poised to revolutionize a wide range of applications.

Grilamid TR

Introducing Grilamid TR, the revolutionary amorphous transparent polyamide that redefines the boundaries of sustainability and performance. Crafted from renewable castor oil, Grilamid TR embodies the essence of innovation, offering exceptional transparency and a host of remarkable properties that surpass conventional amorphous thermoplastics.

Key Features:

- High Bio-content: Up to 54% bio-based content, making a significant contribution to a reduced environmental footprint.

- Unparalleled Transparency: Crystal-clear transparency rivaling that of glass, allowing for designs that showcase the true essence of your products.

- Natural Color: Grilamid TR’s natural color eliminates the need for pigmentation, reducing environmental impact and cost.

- Exceptional Chemical Resistance: Grilamid TR exhibits superior chemical resistance compared to most other amorphous thermoplastics, making it ideal for applications involving harsh chemicals.

- High Gloss and Scratch Resistance: Grilamid TR boasts a high gloss finish and exceptional scratch resistance, ensuring that your products retain their pristine appearance for years to come.

- Low Density: Grilamid TR’s lightweight nature contributes to enhanced sustainability and reduced material consumption.

- Excellent Adhesion to Grilamid 1S (PA1010): Grilamid TR seamlessly adheres to Grilamid 1S (PA1010), enabling innovative overmolding and sandwich molding processes.

Transcend Traditional Limits with Grilamid TR

Grilamid TR represents a paradigm shift in amorphous transparent plastics, breaking free from the constraints of conventional materials. Its exceptional transparency, remarkable chemical resistance, and eco-friendly credentials make it the ideal choice for a wide range of applications, from consumer electronics to automotive components and medical devices.

Grivory HT3 (PPA)

Introducing Grivory HT3 (PPA), the groundbreaking polyphthalamide that seamlessly blends exceptional performance with a commitment to sustainability. Crafted from renewable castor oil, Grivory HT3 (PPA) offers a range of remarkable properties that set it apart from conventional PPAs.

Key Features:

- High Bio-content: Up to 48% bio-based content, significantly reducing the environmental footprint of your products.

- Ultra-low Moisture Absorption: Exceedingly low moisture absorption compared to other PPAs, ensuring dimensional stability and resistance to hydrolysis.

- Unmatched Dimensional Stability: Grivory HT3 (PPA) maintains its shape and integrity under varying environmental conditions, making it ideal for applications demanding dimensional stability.

- Exceptional Chemical and Hydrolysis Resistance: Grivory HT3 (PPA) exhibits superior resistance to harsh chemicals and hydrolysis, ensuring long-term durability and performance.

- High Peak Temperature and Heat Resistance: Grivory HT3 (PPA) can withstand extreme temperatures, making it suitable for applications involving high heat exposure.

- Lead-free Soldering Compatibility: Grivory HT3 (PPA) is compatible with lead-free soldering processes, reducing environmental impact and ensuring compliance with RoHS regulations.

- Halogen-free Flame-retardant Compound for E&E Applications: Available as a halogen-free flame-retardant compound, Grivory HT3 (PPA) meets the stringent requirements of electronic and electrical applications.

Revolutionize Your Applications with Grivory HT3 (PPA)

Grivory HT3 (PPA) represents a leap forward in polyphthalamide technology, offering a unique combination of exceptional performance, sustainability, and versatility. Its ability to withstand extreme temperatures, maintain dimensional stability, and resist harsh chemicals makes it ideal for a wide range of applications, from automotive components to medical devices and consumer electronics.