Your Polymer Partner

Call Us Now+886 2 8729 9199

Automotive

Engineering polymers are a diverse class of materials that are used in a wide range of industries, including automotive, consumer goods, electrical/electronics, sports, and medical/healthcare.

Automotive

Engineering polymers are used in a variety of automotive applications, including:

. Battery management for New Energy Vehicles

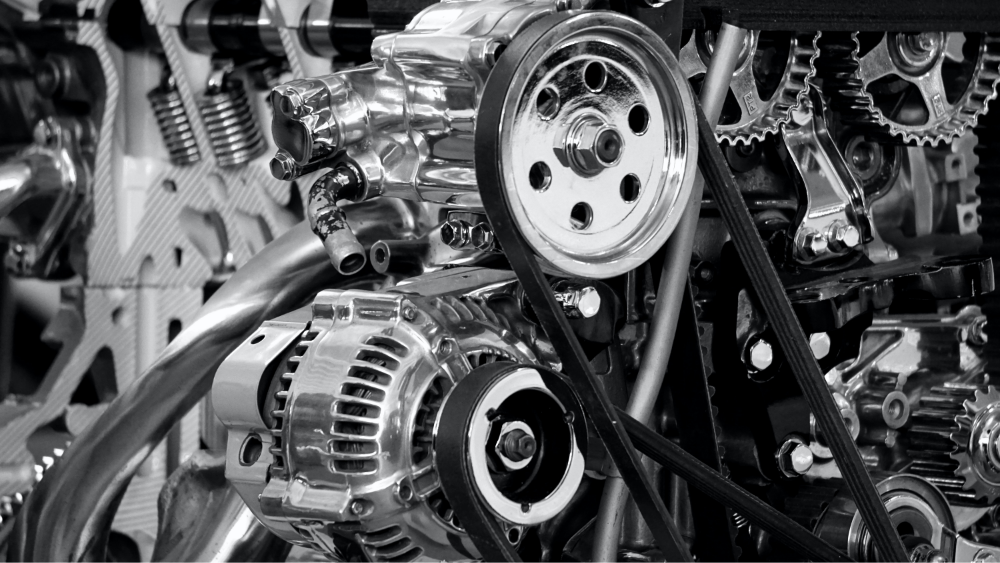

. Engine components

. Interior trim

. Electrical and electronic components

. Battery management for New Energy Vehicles

. Engine components

. Interior trim

. Electrical and electronic components

Engineering polymers offer several advantages for automotive applications, including:

Lightweight:

Engineering polymers can help to reduce the weight of vehicles, which can improve fuel efficiency and reduce emissions.

Corrosion-resistant:

Engineering polymers are resistant to corrosion, making them ideal for use in harsh environments.

Strong/durable:

Engineering polymers are strong and durable, making them suitable for a variety of demanding applications.

Easy to process:

Engineering polymers are relatively easy to process, which can help to reduce manufacturing costs.

Engineering polymers are used in a variety of automotive applications, accounting for more than 1,000 components in a modern car today. These components represent just 10% of the car’s weight, but they play a vital role in reducing fuel consumption and emissions. For example, a study by the US Department of Energy found that reducing the weight of a car by 10% can improve fuel economy by 5 to 7%.

Engineering polymers are also used to replace metal components, which can reduce costs by up to 35%. For example, polycarbonate is used to make lightweight and durable bumpers, while polyamides are used from gears to High temperature resistant under the bonnet applications.

Engineering polymers are also used to replace metal components, which can reduce costs by up to 35%. For example, polycarbonate is used to make lightweight and durable bumpers, while polyamides are used from gears to High temperature resistant under the bonnet applications.

Applications

Under the hood

Powertrain

Thermal management

Transmission

Fuel system

Air Ducts

Gasket

Water tank grille

Spoiler

Suspension

Brake Booster Valves

Electrical / EV

Sensors

Electric control units

Connectors

Wire harness

Switches, relays

Bus Bar

Cooling lines

Charging station panel

Cable jacket

Exterior

Light

Trims

Mirrors

Antenna

Interior

Cross beam

Cup holders

Air vents

Seat shells

Gasket

Overmolding parts

Products

Polyamides (PA):

Polyamides are widely used in automotive applications for their excellent mechanical properties, heat resistance, and durability. In NEVs, they are used in battery components, connectors, and structural parts. In ICEs, they find applications in engine components, fuel systems, and interior parts.

With the automotive industry transitioning towards lightweighting and electrification, polyamides play a vital role. Their versatility allows for customization to meet the specific needs of both NEVs and ICEs, contributing to improved fuel efficiency, reduced emissions, and overall vehicle performance. Furthermore, with the evolution of the automotive industry the demand for materials capable of withstanding higher temperatures and providing long-term reliability increases. PPAs like Grivory HT contribute to the development of high-performance components that support the transition to electric and hybrid vehicles

With the automotive industry transitioning towards lightweighting and electrification, polyamides play a vital role. Their versatility allows for customization to meet the specific needs of both NEVs and ICEs, contributing to improved fuel efficiency, reduced emissions, and overall vehicle performance. Furthermore, with the evolution of the automotive industry the demand for materials capable of withstanding higher temperatures and providing long-term reliability increases. PPAs like Grivory HT contribute to the development of high-performance components that support the transition to electric and hybrid vehicles

TPE (Thermoplastic Elastomer) :

Empilon TPEs combine the properties of plastics and elastomers. They are strong, flexible, and elastic, and they can be processed into a variety of shapes and forms. Empilon grades are used in a variety of automotive applications, including seals, gaskets, and hoses.

Post-Consumer Recycled (PCR) Polycarbonate, PC/ABS, or OBP ABS:

Sustainable materials like PCR Polycarbonate or PC/ABS with recycled content can be employed in automotive interiors, exterior trims, and under-the-hood components for both NEVs and ICEs, aligning with the automotive industry’s push towards sustainability.

With the global focus on reducing environmental impact, incorporating recycled materials in automotive applications contributes to circular economy practices, meeting consumer expectations and regulatory standards for sustainable mobility.

With the global focus on reducing environmental impact, incorporating recycled materials in automotive applications contributes to circular economy practices, meeting consumer expectations and regulatory standards for sustainable mobility.

Bio-based Polyamides and TPE:

Bio-based polyamides and TPEs offer a sustainable alternative for automotive applications. In NEVs, they can be used in interior components and non-structural parts. In ICEs, bio-based materials contribute to reducing the carbon footprint in various applications.

The shift towards sustainable mobility requires bio-based alternatives that reduce dependence on fossil fuels. Bio-based polyamides and Empilon TPEs contribute to the development of eco-friendly vehicles, supporting the automotive industry’s commitment to environmental responsibility.

The shift towards sustainable mobility requires bio-based alternatives that reduce dependence on fossil fuels. Bio-based polyamides and Empilon TPEs contribute to the development of eco-friendly vehicles, supporting the automotive industry’s commitment to environmental responsibility.

Sulfone Polymers (PPSU, PES, PEI):

Sulfone polymers, with their high-temperature resistance and chemical stability, find applications in automotive components requiring durability and resistance to harsh conditions. They can be used in both NEVs and ICEs for various under-the-hood and structural parts.

The trend towards higher efficiency and durability in vehicles necessitates materials that can withstand demanding conditions. Sulfone polymers contribute to the development of lightweight, high-performance components in the automotive sector.

The trend towards higher efficiency and durability in vehicles necessitates materials that can withstand demanding conditions. Sulfone polymers contribute to the development of lightweight, high-performance components in the automotive sector.

Conclusion:

The strategic use of these materials in the Automotive segment addresses the unique challenges posed by the shift towards electrification and sustainability. By prioritizing customization, sustainability, and technological compatibility, businesses can better serve the automotive market and contribute to the development of advanced, eco-friendly vehicles for the future.

The use of these polymers can help to:

- Reduce weight: Lighter vehicles improve fuel efficiency and reduce emissions.

- Reduce costs: The use of these polymers can help to reduce the cost of manufacturing vehicles.

- Improve performance: These polymers can be used to create stronger, stiffer, and more heat-resistant parts, which can improve the performance of vehicles.

- Enhance safety: These polymers can be used to create safer vehicles by protecting occupants in the event of a crash.

- Improve product quality: The use of these polymers can help to improve the quality of vehicles.

- Increase customer satisfaction: The use of these polymers can help to improve customer satisfaction by creating vehicles that are more fuel-efficient, more performant, and safer.