Your Polymer Partner

Call Us Now+886 2 8729 9199

Industry

Engineering polymers are a diverse class of materials that are used in a wide range of industries, including automotive, consumer goods, electrical/electronics, sports, and medical/healthcare.

Industry

In the industrial sector, long-term resistance to heat, hot water, and chemicals are common requirements. Extensive data have been collected on industry-specific applications to simulate years of usage. Our data have been measured in stagnant and flowing water with and without chloramine. High-performance polymers are used in various applications such as automation, valve islands, pressure regulators, rollers, bearing cages, tubes, etc.

Applications

Pneumatic & Hydraulic

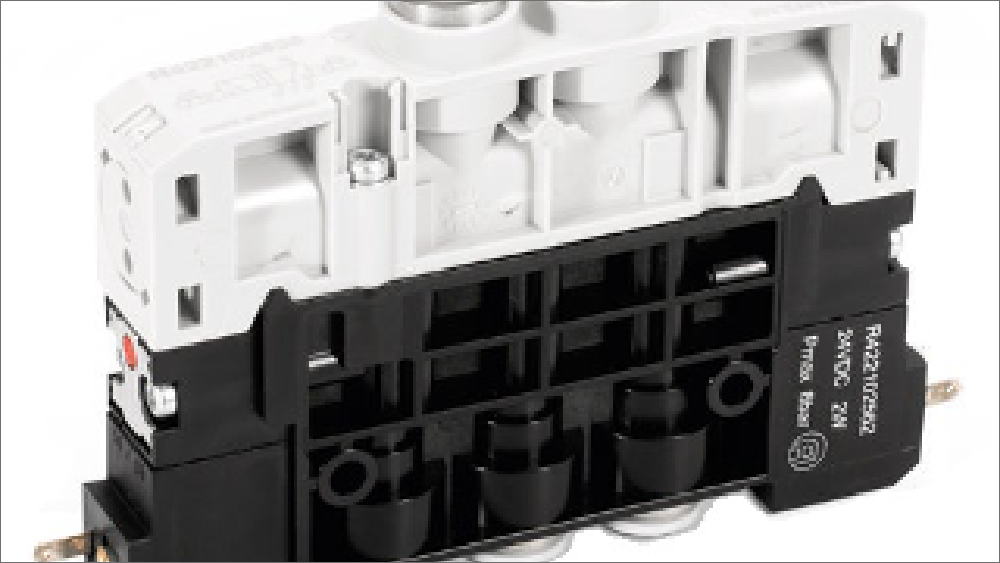

Valve island

Solenoid Valves

Tubes

Vacuum System

Filter cups

Protection hose

Automation

Production line components

Air filter

Rollers

Bearing cages

Linear guides

Grippers

Production line components

Air filter

Rollers

Bearing cages

Linear guides

Grippers

Water managment

Water meter

Water filters

Pressure valve

Plumbing

Water Ways / Faucets

Gages

Filter bowls

Valves

Water Mixers

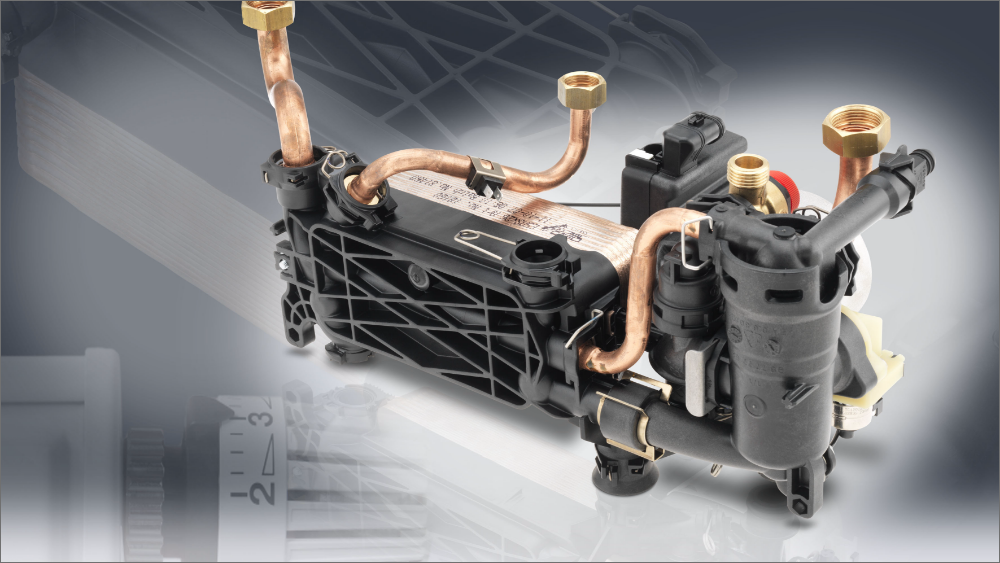

Boiler/Heater

Products

In the dynamic intersection of industry and plumbing, the judicious selection of polymers is pivotal for achieving optimal performance and addressing evolving challenges. Let’s explore the profound relevance of Polyamides, Polyphthalamide (PPA), Post-Consumer Recycled (PCR) Polycarbonate, PC/ABS or OBP ABS, Thermoplastic Elastomers (TPE), and Sulfone Polymers (PPSU, PES, PEI) in this unified context.

Polyamides (PA) and Polyphthalamide (PPA) in Industry: Polyamides, known for their versatility, offer a combination of strength, durability, and resistance. PPA, a specialized polyamide, excels in demanding industrial and machinery applications, finding utility in mechanical components like gears, bearings, and electrical components such as insulators, connectors, and housings. Fluid handling components like pipes, valves, and fittings benefit from their corrosion and chemical resistance, while precision parts and chemical processing equipment rely on PPA’s low creep, stiffness, and chemical resistance.

PCR Polycarbonate, PC/ABS, or OBP ABS in Industry: Sustainable alternatives are integral to minimizing environmental impact. PCR Polycarbonate and PC/ABS or OBP ABS blends find application in machine guards, safety shields, and enclosures, ensuring workplace safety with impact-resistant and environmentally responsible materials.

TPEs in Industry: The unique properties of TPEs, combining plastic and elastomers, find utility in seals, gaskets, and vibration damping components in industrial settings. Bio-based TPEs add a sustainable dimension to applications, such as gasketing materials and protective covers.

Sulfone Polymers (PPSU, PES, PEI) in Industry: Sulfone polymers, valued for strength, heat resistance, and chemical resilience, excel in demanding industrial environments. They play a pivotal role in high-performance machinery components, extreme temperature applications, and corrosion-resistant components for chemical processing equipment and wastewater treatment systems.

Polyamides and Sulfone Polymers in Plumbing: Polyamides (PA) and PPA find application in plumbing for pipes, fittings, fixtures, and hot water systems, leveraging durability, chemical resistance, and ease of processing.

PCR Polycarbonate, PC/ABS, or OBP ABS contribute to sustainable plumbing fixtures, incorporating recycled content to align with environmental consciousness.

Bio-based Polyamides and TPE offer sustainability in plumbing applications, including seals, gaskets, and handles.

Sulfone Polymers contribute to durable and reliable water treatment components as the demand for advanced water treatment and filtration systems increases.

Polyamides (PA) and Polyphthalamide (PPA) in Industry: Polyamides, known for their versatility, offer a combination of strength, durability, and resistance. PPA, a specialized polyamide, excels in demanding industrial and machinery applications, finding utility in mechanical components like gears, bearings, and electrical components such as insulators, connectors, and housings. Fluid handling components like pipes, valves, and fittings benefit from their corrosion and chemical resistance, while precision parts and chemical processing equipment rely on PPA’s low creep, stiffness, and chemical resistance.

PCR Polycarbonate, PC/ABS, or OBP ABS in Industry: Sustainable alternatives are integral to minimizing environmental impact. PCR Polycarbonate and PC/ABS or OBP ABS blends find application in machine guards, safety shields, and enclosures, ensuring workplace safety with impact-resistant and environmentally responsible materials.

TPEs in Industry: The unique properties of TPEs, combining plastic and elastomers, find utility in seals, gaskets, and vibration damping components in industrial settings. Bio-based TPEs add a sustainable dimension to applications, such as gasketing materials and protective covers.

Sulfone Polymers (PPSU, PES, PEI) in Industry: Sulfone polymers, valued for strength, heat resistance, and chemical resilience, excel in demanding industrial environments. They play a pivotal role in high-performance machinery components, extreme temperature applications, and corrosion-resistant components for chemical processing equipment and wastewater treatment systems.

Polyamides and Sulfone Polymers in Plumbing: Polyamides (PA) and PPA find application in plumbing for pipes, fittings, fixtures, and hot water systems, leveraging durability, chemical resistance, and ease of processing.

PCR Polycarbonate, PC/ABS, or OBP ABS contribute to sustainable plumbing fixtures, incorporating recycled content to align with environmental consciousness.

Bio-based Polyamides and TPE offer sustainability in plumbing applications, including seals, gaskets, and handles.

Sulfone Polymers contribute to durable and reliable water treatment components as the demand for advanced water treatment and filtration systems increases.

The Future Outlook:

- Customization for Efficiency: Collaborate with manufacturers for tailored solutions that enhance machinery efficiency and performance.

- Sustainability Integration: Embrace sustainable materials to meet eco-conscious consumer demands and adhere to environmental regulations.

- Technological Compatibility: Stay attuned to technological advancements to ensure materials are compatible with evolving industrial processes.

- Regulatory Adherence: Comply with stringent industry regulations, ensuring safety and environmental standards are met.

In the intricate tapestry of industry and plumbing, these polymers are not just materials; they are enablers of progress. Their strategic use aligns businesses with a future defined by enhanced performance, sustainability, and innovation. By staying ahead of industry trends and prioritizing the unique needs of each sector, businesses can not only thrive but also contribute to a future of efficient, eco-friendly, and advanced solutions.